Welcome to Rouen Paper Mill

Take the Virtual Tour

Follow the papermaking process from our quality hub to dispatch, learn how all the machines work, and meet the people that make it all possible.

What you can see on the tour:

- Raw materials Recycling quality hub – learn about our rigorous quality checks and standards when paper arrives at the mill

- Stockyard - find out how we pick the perfect blend of fibres to make our high-quality papers

- Pulper – this is where we process fibres ready for our papermaking machines

- Paper machine – discover how pulp is turned into paper

- Warehouse – see where we store our paper

- Dispatch – Now our paper is ready to head off to our packaging plants all over Europe, ready to be turned back into new products

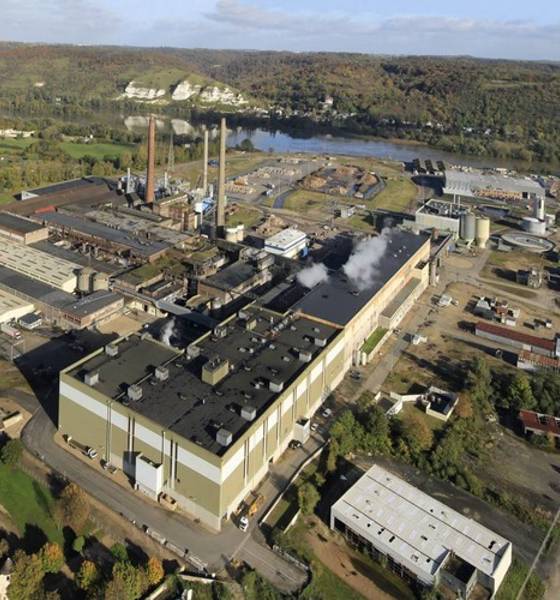

About Rouen Paper Mill

Products

- MediumPAC

- LightPAC

- MultiPAC

Machinery

PM5 SINGLE LAYER MACHINE

| Grammage range: | 85-130 g/m2 |

| Production: | 300,000 tonnes/year |

| Speed max: | 1,100 m/min |

| Trim max: | 6.90 m |

Milestones

- 1928

The mill was founded, producing newsprint paper from mechanical pulp with two paper machines. - 1936

Start-up of two new paper machines, both producing light weight coated paper. - 1958

Start-up of current PM5. At the time Rouen was the biggest paper mill in Europe producing newspaper. - 1998

Production of light weight recycled fluting. - 2006

PM3 and PM4 are closed. Current PM5 specialises in low grammage grades. Production capacity was 220,000 tonnes per year. - 2011

Installation of a shoe-press to achieve 270,000 tonnes per year production capacity.

- 2015

Installation of a new winder. - 2019

Several investments to achieve 280,000 tonnes per year production capacity. - 2020

First phase of investment for plastic reject treatment. - 2021

Launched sustainability initiative to support bees and pollinators in urban environment. - 2021

Start-up of our second methaniser and new aerobic tank to ensure higher quality plastic rejects. - 2022

Second phase of investment for plastic reject treatment at Stock Prep.