Complete line solutions

We can provide a complete line solution tailored to your needs.

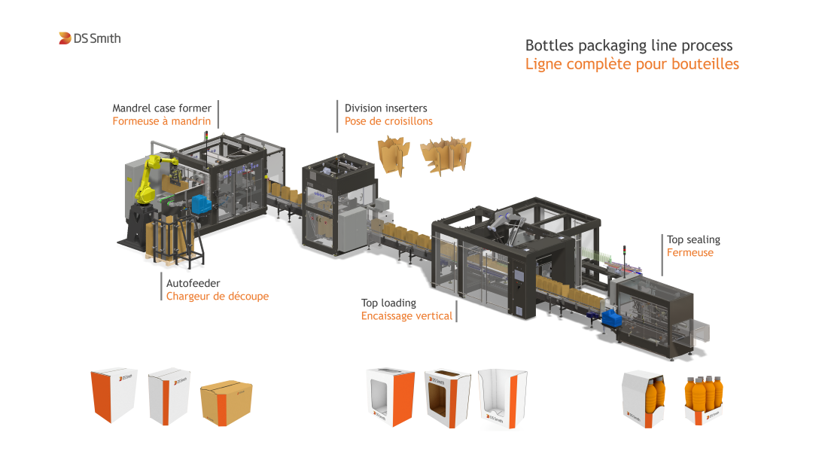

Bottles packaging line process :

A complete bottle packaging line consists of:

- A cardboard blank auto-feeder picks up the flat blanks and feeds them into the magazine.

- A mandrel case former produces perfectly square cases, enabling the process to run smoothly.

- A partition inserter inserts the 6- or 12-bottle partitions into the formed case.

- A top loader (EVA loader) fills the cases with bottles.

- A top sealer performs the final task before palletisation.

-------------------------------------------------------------------------------------------

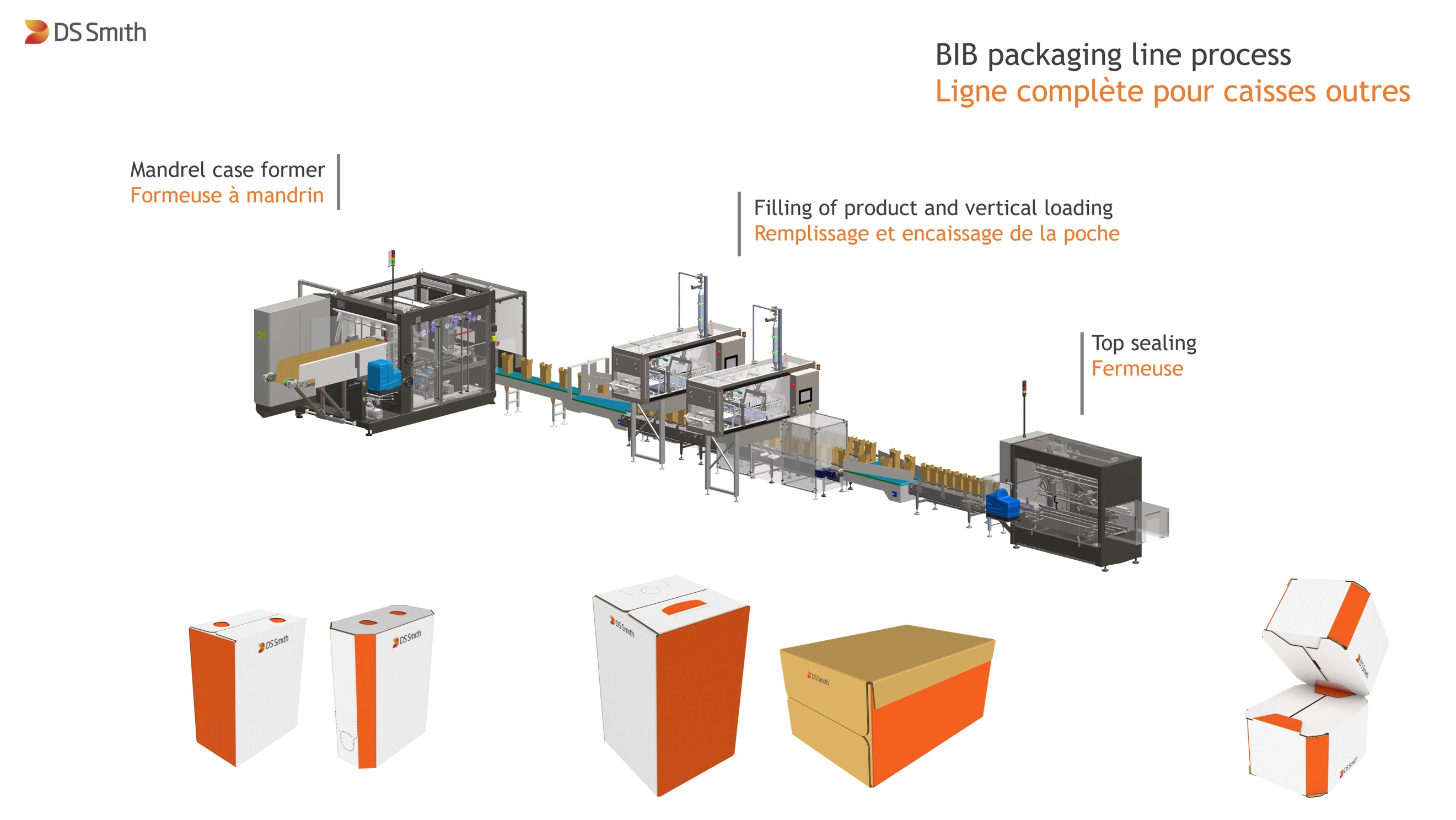

Bag-in-Box packaging line process :

Complete Bag-in-box line consist:

- A cardboard blank auto-feeder picks up the flat blanks and feeds them into the magazine.

- A mandrel case former produces perfectly square cases, enabling the process to run smoothly.

- Packing : 1 or 2 head fiiling of products and vertical loading inside the bags 1,5 to 20 litres

- A top sealer performs the final task before palletisation.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

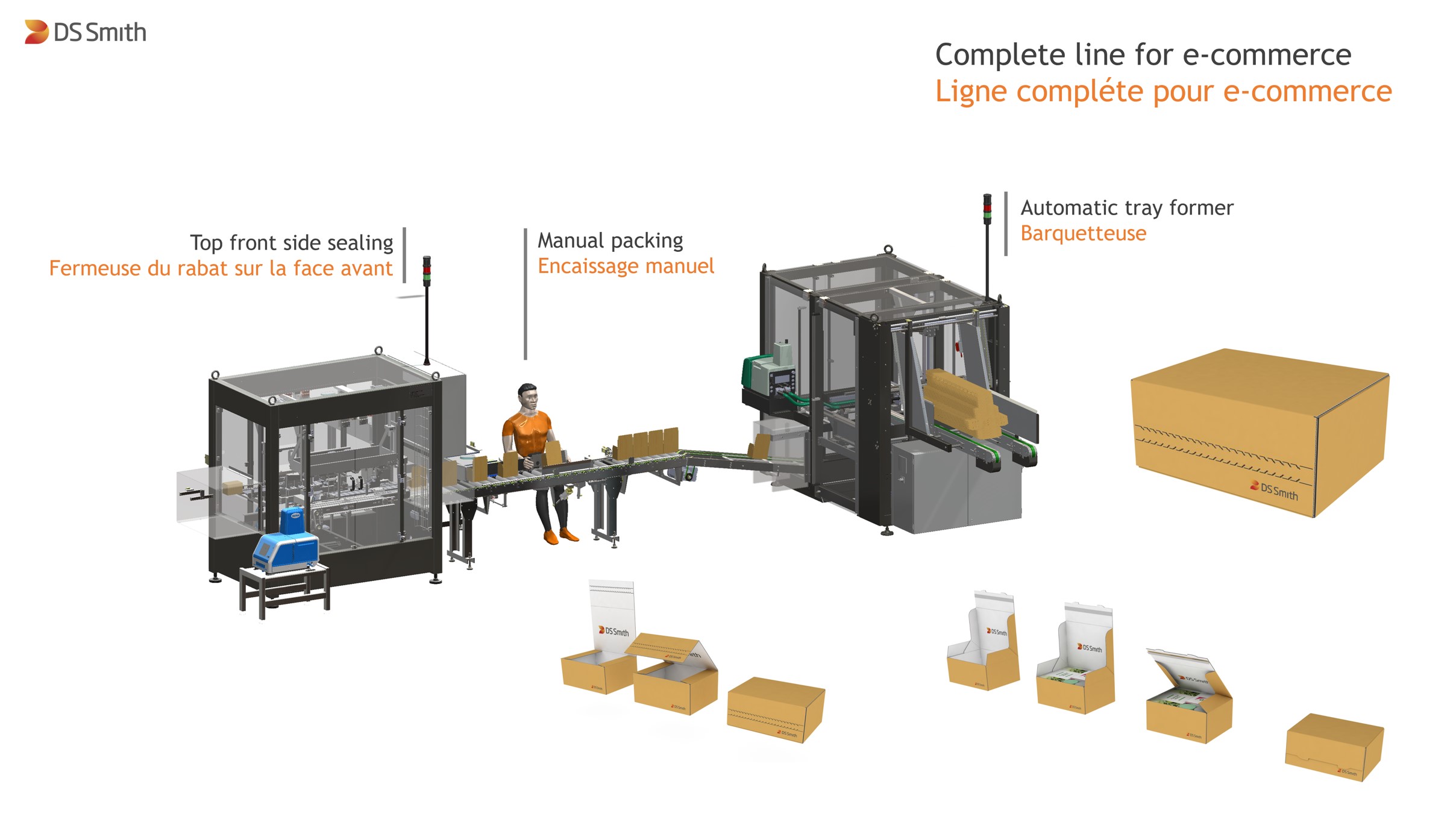

E-commerce & logistic packaging line process :

Complete e-commerce & logistic line consist :

Complete e-commerce & logistic line consist :

- Automatic Tray former produces tray inside cavity with covering top flaps.

- Packing : 1 or several operators fill products manually inside the tray and order sheet. Packing operation can be automatized.

- Sealing : specific top front sealing machine ensure a perfect closing. Fast opening design and tray can be reused.

Contact us to find out more.