End-of-line packaging machines

DS Smith Packaging Systems provides you a complete range of end-of-line packaging machines.

With more than 35 years of experience and a design office with more than 20 engineers, we develop innovative solutions taking into account your evolutive machinery needs.

Our range goes from mandrel case formers or tray formers, bag-in-box, partition inserter, case packers to case sealers. We also handle customised solutions for loading or manual forming of your corrugated packaging.

4 pillars

Our TCO approch

The value proposition is our promise to customers of all the benefits and values they will experience by using our products and services.

We focus on your business needs to help you more sales, reduce costs, managed risk and economy circular.

Using a unique way of working, our highly skilled teams work closely with each client to design packaging that delivers real results: increased sales, reduced costs and managed risk in a sustainable way. Concretely, this means:

- Identifying how packaging can support your marketing efforts and catch the eye of the consumer at the point of sale.

- Protecting products and minimising the amount of cardboard produced

- Optimising space in the packaging, in the warehouse and at the point of sale

- Responding to change and providing scalable solutions

- Controlling recycling

Four key benefits

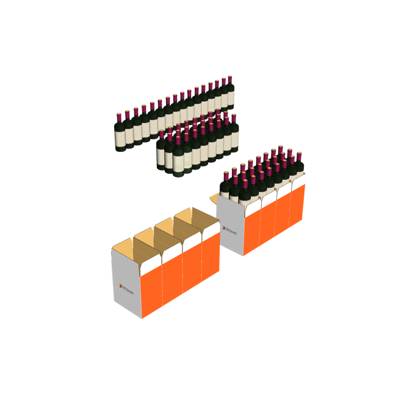

Our machinery boosts your sales by enabling you to produce packaging that catch the consumer’s eye at the point of sale. This highlights your brand and your products on the shelf by producing outstanding shelf impact.

Our solutions enable you to reduce the grammage and minimise the amount of cardboard required in your packaging through perfect squaring and consistently accurate case dimensions while improving its resistance strength to compression (BCT ). Our packaging is eco-friendly and provides optimization along the whole process (cardboard, costs, transport, logistics and storage).

Our solutions enable you to reduce the grammage and minimise the amount of cardboard required in your packaging. Logistics costs are reduced by optimising the transport and storage of cardboard blanks by delivering them flat and by maximising your pallet fill rate. This also reduces the cost of wrapping accessories.

Our solutions help to limit your risks by improving the productivity of your production floor and the working conditions of your employees. Line stoppages are reduced by perfect and consistent case squaring, and rates of musculoskeletal disorders (MSDs) are lowered owing to the excellent ergonomics and accessibility of our machinery.