DS Smith Tecnicarton designs returnable Tecnipack to reduce handling of large parts on the assembly line

•The solution has been developed for bus manufacturer Heuliez Bus, which was looking to replace its wooden packaging with more functional ones.

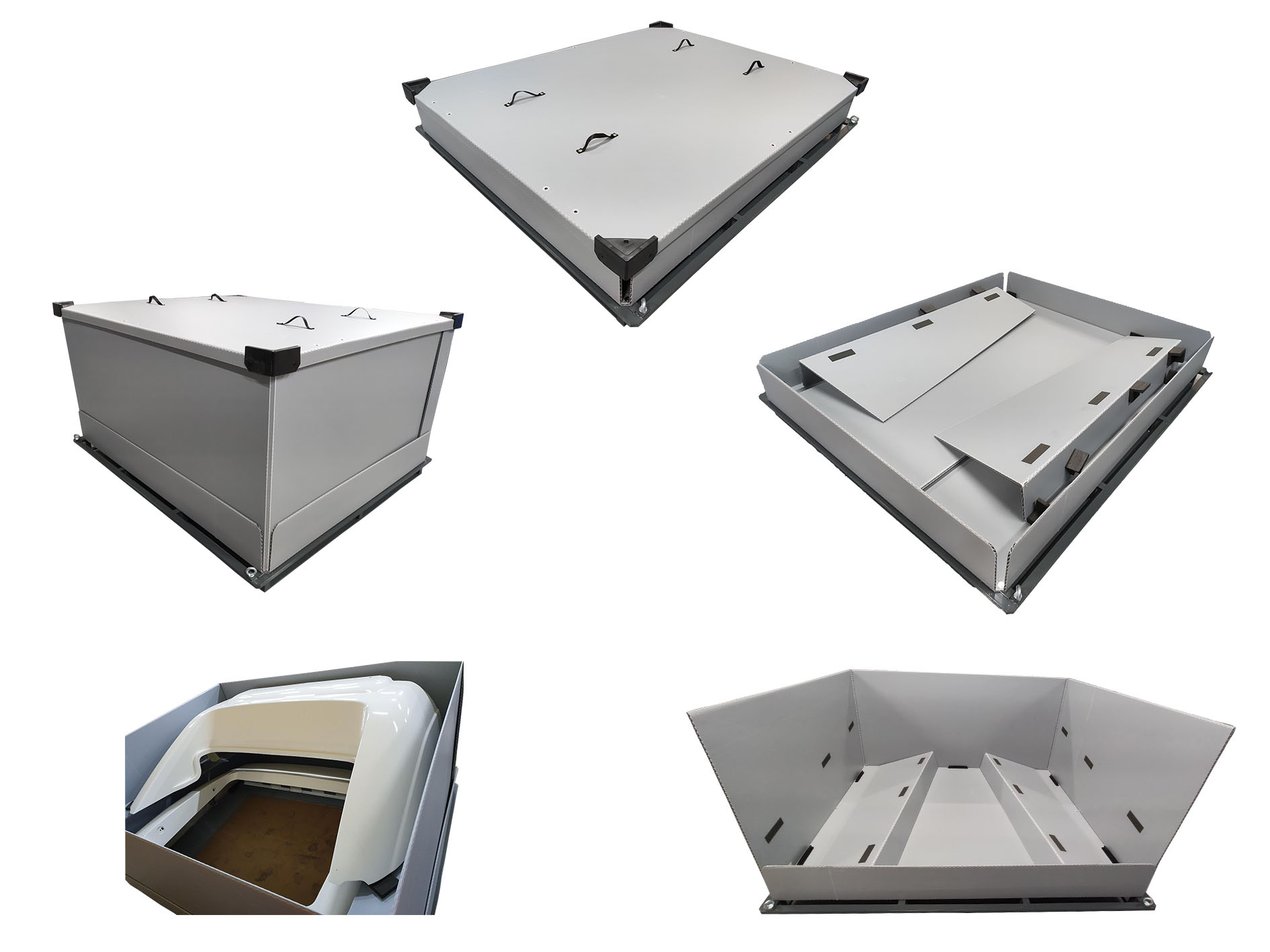

DS Smith Tecnicarton has designed a bespoke returnable Tecnipack that significantly reduces the handling of large parts on the assembly line. This solution is produced at the company's plant in France for bus manufacturer Heuliez Bus, which until now has been using wooden crates.

The main challenge in the design of this packaging was to adapt it to the large dimensions and make it functional in its interaction with the production line. The solution provided is a custom-designed folding Tecnipack, with a metal base and eyebolts so that it can be lifted with slings and hooks.

This packaging optimizes logistics and improves safety, as it reduces the handling of parts on the assembly line and allows two types of parts to be stored in perfect arrangement. The design also makes it possible to reduce the number of operators needed to place and pack the parts.

In addition, it is a returnable and reusable solution, which gives it a great advantage over other types of packaging due to its more competitive price.

As Antonio Cebrián, Commercial Director of DS Smith Tecnicarton, points out, this development is in line with the company's commitment "to offer customized, innovative and sustainable solutions that respond to the needs of our customers".